Industrial Sales & Manufacturing (ISM), a family-owned company known for comprehensive manufacturing capabilities, has successfully integrated LightWELD technology into its operations. The Erie, Pennsylvania-based company serves diverse industries, including transportation, mining, energy, medical, and agriculture.

Industrial Sales & Manufacturing (ISM), a family-owned company known for comprehensive manufacturing capabilities, has successfully integrated LightWELD technology into its operations. The Erie, Pennsylvania-based company serves diverse industries, including transportation, mining, energy, medical, and agriculture.

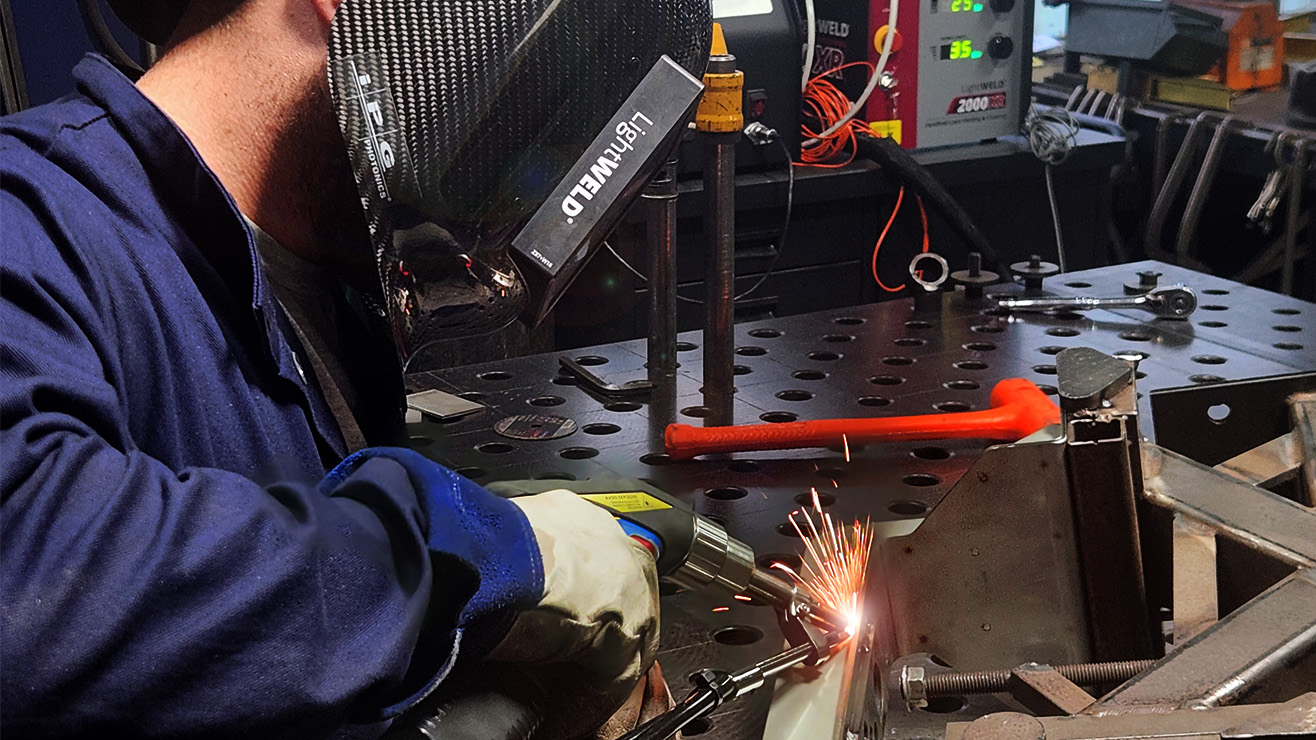

ISM invested in three LightWELD units to improve weld quality and tackle challenging applications. The results have been significant – the technology has reduced post-processing requirements, minimized warping issues, and helped address skilled labor shortages.

“With LightWELD, we don’t have to do any spatter cleanup or tweaking. We weld the parts together, nothing moves, it’s awesome,” says Joe Tomasik, Process & Estimation Manager and Plant Engineer at ISM.

The company’s executive team, including Charlie Rutkowski, Executive VP of Operations, emphasizes that embracing new technology helps them maintain competitiveness while upholding their high-quality standards. Regular validation by Certified Welding Inspectors confirms consistently superior weld quality.