Equipment

The ISM equipment inventory ensures a level of capability, reliability and productivity few companies can match. From the latest CNC machines, Flexible Machining Systems, Robotic Welding Systems, Plasma and 3D Laser Cutting equipment, over 120 machines provide nearly every conceivable Machining, Fabrication, Assembly, Testing and Finishing operation customers require.

Our Commitment. Our continual investment in state-of-the-art equipment across all services ensures ISM customers receive the highest level of quality. Over the past five years we have invested over $10 million in equipment with more planned each year. Productivity is assured through the strength of ISM’s maintenance and set-up programs to keep machines operating at optimum speed and feed cycle times.

Equipment Redundancy. ISM believes no customer order should ever be delayed due to an unplanned event. Virtually every machine and piece of equipment is backed-up with at least one machine that can perform the operation in the event of an unplanned shut-down. This level of redundancy ensures project quality and adherence to schedule will not be impaired due to equipment failure.

Reliability. To ensure machine reliability and performance, ISM utilizes the RPM (Repair, Prevention, Modification) program. RPM tracks and prioritizes maintenance activity to ensure downtime is at the very minimum. The highly trained maintenance crew is scheduled around the clock and at times when machines are not in use to assure the highest level of reliability.

LEARN MORE about ISM equipment and capabilities by clicking the links below.

- Komatsu Razor Fine Plasma Cutting Machine(Hi Definition) Up to 1-1/8” x 6’ x 12’ steel, stainless, & aluminum

- DoAll Job Selector Saw C-3300

- DoAll C70 Automatic Power Saw

- Johnson Model “J” Horizontal Cutoff Saw 9" x 16"

- Johnson Model “B” Horizontal Cutoff Saw 4" x 12"

- Grob 20" Vertical Band Saw

- Everett 12" Abrasive Cutoff Saw

- Everett 16" Abrasive Cutoff Saw

- Mazak Space Gear Cutter

- Nishijimax Saw

- Mazak Dual Turn 20 with Flex-GL 100 Automatic Loader with a Mazatrol Fusion 640T CNC Control

- Mazak Quick Turn 20 H-P with a Mazatrol T-Plus Control

- Mazak Quick Turn 25C with a Mazatrol T-Plus Control

- Mazak Quick Turn 8N with a Mazatrol T32-2 Control

- Mazak Quick Turn 15N with a Mazatrol T32-B Control

- Mazak Quick Turn 15N with a Mazatrol T32-B Control

- #55b Galymeyer & Livingston Surface Grinder

- #35 Galymeyer & Livingston Surface Grinder

- #25 Galymeyer & Livingston Surface Grinder

- Delta Tool & Cutter Grinder

- Porter Cable 6" Double End Tool Grinder

- Mohawk Model 302 Drill Grinder

- Arter Grinder 1

- Reid Model 612H Surface Grinder

- Blanchard Grinder

- Cincinnati Centerless Grinder

- Grands Rapid Grinder 18 x 32

- Norton #1

- Norton 3415013

- Mazak FH-480 Horizontal Machining Center:

- 24 Tool (20”x20”x20”) Mazatrol M-Plus Control

- Mazak HTC-400 Horizontal Machining Center:

- 24 Tool (20”x20”x20”) Mazatrol M-Plus Control

- Mazak VTC-16 Vertical Machining Center:

- 24 Tool (22"x16"x20") Maztrol M-32 Control

- Mazak VQC/1540 Vertical Machining Center:

- 16 Tool (22"x16"x15") Mazatrol M-32 Control

- Mazak VTC-20 Vertical Machining Center

- 24 Tool (44"x20"x20") Mazatrol M-32 Control

- FADAL VMC 4020 Vertical Machining Center:

- 21 Tool (40"x20"x28") FADAL CNC88HS Control

- FADAL VMC 3016L Vertical Machining Center:

- 21 Tool (30”x16”x20”) FADAL CNC88HS Control

- FADAL VMC 15 Machining Center

- 21 Tool (20"x16"x20") FADAL CNC88HS Control

- Mazak Flexible Manufacturing System

- 4" x 9" American Radial Drill

- 4" x 12" Column Soraluce Radial Drill

- Clausing 15" Drill Model 1675

- Clausing 15" Drill Model 1771 with Power Feed

- Fosdick 15" Drill with Tapping Head

- Special Drilling Machine:

- 20" Clausing & 15" Clausing with Commander Drill Heads

- Dura-Craft Drill Press

- (2) Summit 11" x 30" Tray Top Lathe

- Cincinnati 18" x 30" Tray Top Lathe

- Lodge & Shipley

- (2) Bridgeport 1J Vertical Mill:

- 9" x 42" Table w/Readout

- Cleveland Model RC302 Threader

- Lassy 12F Tapper

- Rigid Pipe Threading Machine

- Colonial Pull Broach

- LaPointe HP-30 Pull Broach

- LaPointe MO-32 Pull Broach

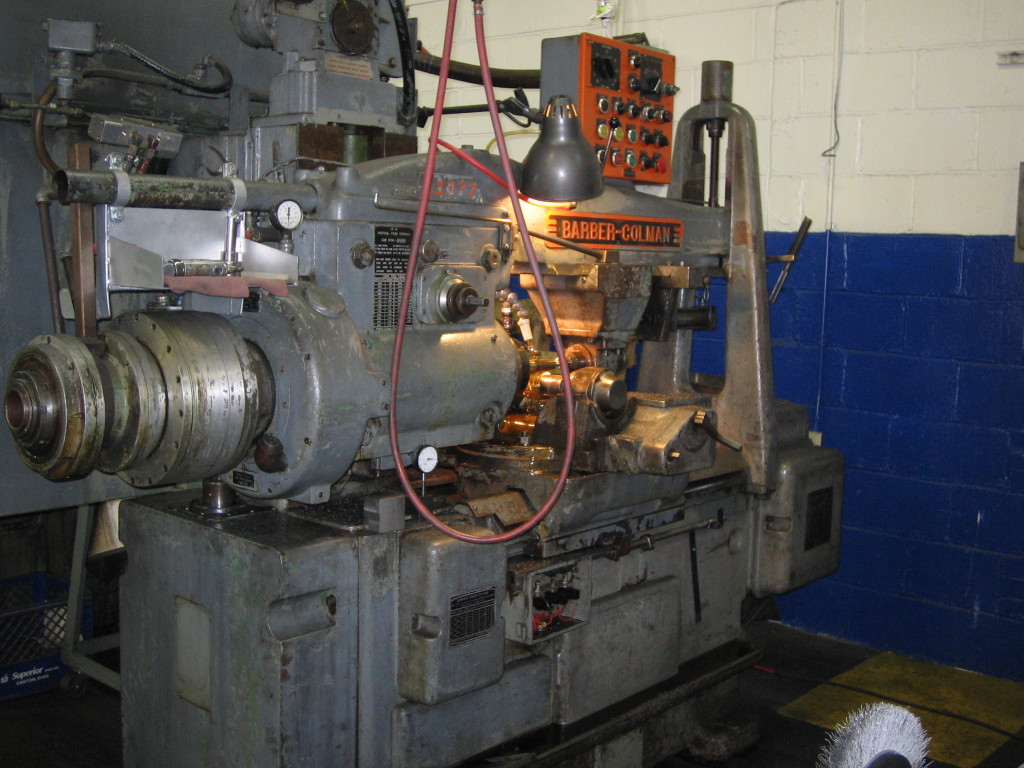

- Barber Coleman Gear HOB 16-16

- Fellows Gear Shaper – 7 minus Type Gear Shaper

- Scotchman 40 Ton Iron Worker

- Heim 150 Ton x 10 FT Bed Mechanical Press Brake

- DiAcro 14 Ton x 4FT Bed Hydraulic Press Brake

- Wysong Shear 14 Ga x 52" LG

- Pexto-Stow Foot Shear 36" x 20 Ga

- (2) DiAcro Hand Punch

- DiAcro #1 Rod Bender

- DiAcro #1A Rod Bender

- DiAcro #4 Rod Bender

- Hossfeld Hydraulic Pipe Bender

- Hydroil Constructer Hydraulic Tube Bender

- Chicago Model 416 Leaf Brake 48" x 16 Ga

- Niagara 30" x 2" Bending Roll

- 10" Dia Crimping Machine

- Consolidated Punch Press 25 Ton Capacity

- V & O #2 Punch Press 15 Ton Capacity

- Pexto 6 ft Power Rolls

- Various Unitool Punch & Shearing Frames

- Cincinnati Shear Capacity 1/4 THK x 10"

- DiAcro Press Brake 75 ton w/ Hurco Backgage

- Motoman AWII Robotic Welding Cell

- (4) Lincoln Mig Welder: Idealarc SP200

- (3) Lincoln Tig Welder: Idealarc 250/250

- 15 KVA American Spot Welder

- (2) Ransome #B1 Welding Table

- (3) Gas Brazing & Welding Sets

- Brancroft Welder

- Motoman AWII Fabworld

- WEBB

- Weld Motion Corp

- Quality Control & Testing Laboratory

- Mitutoyo B706 Coordinate Measuring Machine (X-28" Y-24" Z-18")

- Jones & Lamson Model FC-14 Optical Comparator

- Hydro Static Testing Equipment

- 24" x 18" Black Granite Surface Plate

- 8" x 12" Pink Laboratory Grade Granite Surface Plate

- Mitutoyo Profilemeter

- Wilson Model 4-Our Hardness Tester

- Dermitron Coating Thickness Tester

- Complete Set of Ring, Plug Thread Gages

- Complete Set of Thread Micrometers

- Complete Set of Grade A Gage Blocks

- Complete Set of Pin Gages

- 16" Apex Disc Sander

- Delta 2-1/2" Double Side Belt Sander

- Single End Buffer

- Trinco Dry Blast Machine

- Oil Dip Tank

- Monode Electro-Chemical Etching Unit

- Mead Air-Operated Marking Machine

- Complete Set of Low-Stress Steel Marking Tools

- Complete Spray Booth with Custom Painting Facility

- Complete Line of Cable Swaging Equipment

- Empire Dry Sandblast Machine

- Complete Powder Coating Spray Line

- 3 Stage Part Washer