CNC Machining

From developing a prototype of a new part to the production of hundreds of identical parts, CNC (Computer Numerical Control) equipment enables a higher level of quality, precision and productivity than was possible a few short years ago. Over the past twenty-five years Industrial Sales and Manufacturing, Inc., (ISM) has made a continual investment in state-of –art CNC Milling and Turning equipment. Over the past five years alone ISM has invested over $10 million in CNC machining and quality control equipment. This investment translates to better quality, shorter lead times and a globally competitive price for our customers.

Learn more about our extensive CNC equipment and capabilities. View our Vertical and Horizontal CNC Video here.

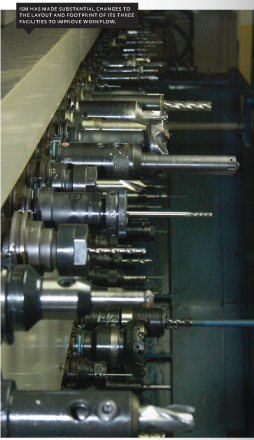

Our CNC shop is designed for efficiency in product flow and operations. This design entails the location of identical machines in machining “cells” that can efficiently be operated by one CNC technician per shift. What used to take 12 technicians can now be performed by one technician per shift.

Our newest CNC acquisitions include Flexible Manufacturing Systems (FMS) capabilities. These systems feature a high level of automation, enabling our company to truly compete on a global level. Our FMS systems use up to 120 tools to work on 45 unique pallets per machine. ISM can machine parts up to 36” cubes of steel, stainless or aluminum.

View the ISM CNC Flexible Machining Systems (FMS) Video to learn more about our CNC Machining capabilities.

As with any technology, proper programing and operation are critical to quality assurance. ISM has invested heavily in systems and software such as the Parlec Visual Tool Center — a high optic camera that ensures CNC equipment is set up correctly for every project. This technology automatically checks customer specifications such as run out and fine-tunes the machine to assure every part is produced as intended. And, every CNC part is inspected resulting in outstanding product quality without sacrificing efficiency.

View our Fixturing & Set-up video on the steps we take to ensure quality of the CNC machined products you can expect as a customer of ISM.

CNC Machining Photos

Thank you once again for your interest in ISM. Let’s start a conversation about your projects and the solutions we can uniquely provide. 814-833-9876

Select A Service

Telephone: 814.833.9876

Fax 814.838.6250

Request A Quote

What are you looking for in a manufacturing partner?

Quick Facts on ISM

- ISM can produce a single component or 300,000 components exactly as ordered, on time, every time, within budget

- ISM specializes in custom orders including quality short & long run projects & emergency work

- ISM is experienced with all types of materials including CF and HF Steel, alloy steel, stainless steel, brass, copper, aluminum and finished-cast products

Machining

- CNC Turning Centers

- CNC Milling & Machining

- Grinding:

- Surface, Cylindrical & Centerless

Assembly

- Custom Assembly

- Sub Contract

- Mechanical Assembly

- Powder Coating & Painting Services

Fabrication

- Custom Assembly

- 3D Laser & Fine Plasma Cutting

- Robotic MIG Welding

- Welding Services: